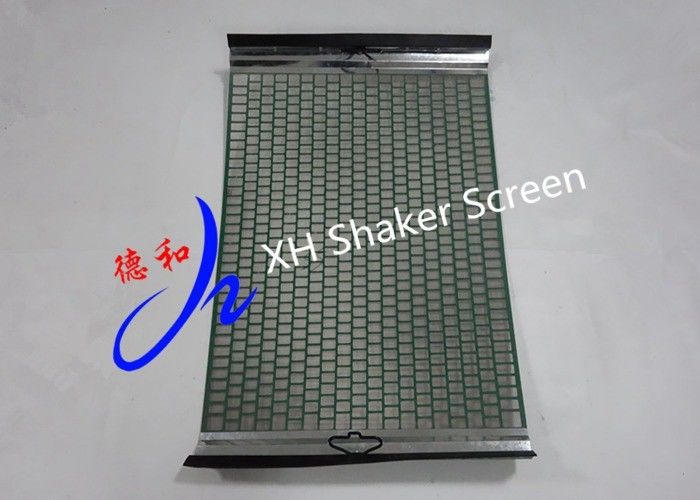

Hookstrip Flat Sand Vibrating Screen Oil Vibrating Screen

1: Quick Detail

Product name: Hookstrip Flat Screen Oil Vibrating Screen for Oilfield Equipment

Size: 1050*695mm

Material: SS316

Colour: Green

Weight: 6 KGS

Wire cloth Layers: 2 or 3 Layers

Mesh count: 20-325mesh

Usage: Liquid Filter

Hook strip Flat Panel Screen is the most common kind of Shale Shaker Screen, which can be widely used in different conditions of drilling operation. This screen is constructed with two/three layers of stainless steel wire cloths bonded to a steel support plank.

We can supply hook strip flat panel screens with the mesh sizes ranging from 20 to 325.

2: Technical Specifications

| Item |

API RP 13C Designation |

layers |

Cut Point 100(micron) |

Conductance

:kd/mm

|

Non-Blanked

Area:sq.ft

|

Weight

(Kg)

|

Dimensions

(W" x L")

|

Mesh Type |

| 500 Flat Shale Shaker Screen |

API 35 |

2/3 |

477.5 |

9.19 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 40 |

2/3 |

411.7 |

8.05 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 45 |

2/3 |

341.1 |

6.20 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 50 |

2/3 |

288.5 |

3.69 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 60 |

2/3 |

243.7 |

3.69 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 70 |

2/3 |

202.7 |

3.69 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 80 |

2/3 |

170.4 |

2.11 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 100 |

2/3 |

142.0 |

1.66 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 120 |

2/3 |

117.8 |

1.30 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 140 |

2/3 |

104.0 |

1.14 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 170 |

2/3 |

85.4 |

0.83 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 200 |

2/3 |

73.3 |

0.72 |

4.05 |

6.5 |

695*1050mm |

DX/XL |

| API 40 |

2/3 |

445.1 |

10.71 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 45 |

2/3 |

331.4 |

8.46 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 50 |

2/3 |

276.0 |

5.40 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 60 |

2/3 |

238.4 |

4.54 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 70 |

2/3 |

197.7 |

3.36 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 80 |

2/3 |

166.6 |

2.34 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 100 |

2/3 |

142.7 |

1.99 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 120 |

2/3 |

117.8 |

1.34 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 140 |

2/3 |

100.6 |

1.16 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 170 |

2/3 |

88.4 |

0.78 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 200 |

2/3 |

71.7 |

0.68 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 230 |

2/3 |

61.0 |

0.46 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 270 |

2/3 |

52.5 |

0.47 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

| API 325 |

2/3 |

44.5 |

0.48 |

4.05 |

6.5 |

695*1050mm |

HP/XR |

3: Products features

Last longer, handle higher flow rates, resist blinding

Single, double, and triple layer screens available

Improved penetration rates, increased shaker capacity

4: Application

The ideal equipment accessories of drilling fluid shale shaker, widely used in drilling operations under different conditions.

5: Advantages

About the plate of our shaker screen, we usually produced the thickness of the plate which was 1.5mm. But according to our clients feedbacks, the plate broken up easily. So we increase the thickness of the plate, now we have the types of the plate is 1.8mm, 2.0mm and 3.0mm.

Now most of the other factories use 1.4mm sheet. So our shaker screen has more longer working life.

About other companies’ shaker screens handles, If the clients are trying to pull the handle maybe the handle comes off. Xinghuo improves the thickness of the handle, so when our screens’ handles are totally straight up, the handle is still very strong.

Regarding the shaker screens’ cloths layers. According to the experience, we usually produce 3 layers cloths when the API mesh ≥140, we usually produce 2 layers cloths when the API mesh < 140. About the cloths layers, we manufacture according to customers’ demands.

6: FAQ

1. Are you a manufacturer or a distributer?

We are a factory.

2. How about your production capacity?

We can manufacture 60000 pieces shaker screens one year.

3. Can you provide free samples?

Yes, we can provide free samples for clients’ testing.

4. What is the material of your cloth?

SS 304 or SS316, according to clients demand.

5. What are the advantages of your shaker screens?

Long working life, higher flow rate, corrosion-resisting, heat-resisting, wear-resisting, easy disassembly, trapping (dreg) effect is good, current design, API compliant shaker screens.

7: Pictures

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!