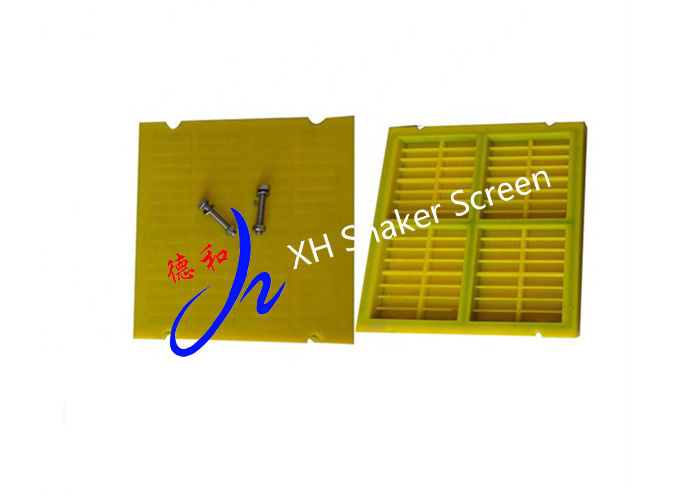

Modular Polyurethane Sand Dewatering Screen Panel For Sieving

1. Description

Material: steel frame and polyurethane surface.

Thickness: 30mm, 45mm, 50mm

Opening size:

Width: 0.1mm - 2.5mm.

Length: 4mm - 16mm.

Screen width: 305mm, 500mm and 515mm.

Screen length: 305mm, 610mm, 650mm, 915mm, 1200mm and 1220mm.

Connection type:

Bolts.

Rose nail.

Trim strip.

Rail support.

Color: red, yellow and any other colors you want.

Polyurethane dewatering screen is a type of screens made of steel frame and polyurethane surface. This structure ensure the high tensile strength and much better wear resistance than the woven vibrating screen mesh and perforated vibrating screen mesh.

Polyurethane dewatering screen is mainly used for dewatering of sand and gravel

Polyurethane dewatering screen is also called polyurethane slot screen because of the narrow slot openings. The narrow slot opening is as fine as 0.1mm, which makes the screen have high efficiency and accurate dewatering performance.

The polyurethane dewatering screen is widely used to assist in dewatering of materials. Additional, it can also provide a ramp which helps to maximize screen washing capabilities.

2. Application

Polyurethane vibrating screen mesh is widely used for the classification of bulk material, such as coal, minerals, coke, beans, etc. So it can be used in the agriculture, chemical industry, minerals, quarry and smelting industries.

Polyurethane vibrating screen can sort the wet materials, it can be used in the water conservancy and hydropower and dewatering industries.

3. Specification

| Panel Width (mm) |

Panel Length (mm) |

Thickness (mm) |

Slot Width (mm) |

Slot Length (mm) |

| 305 |

305 |

30 |

0.1 - 2.5 |

4 - 16 |

| 305 |

305 |

45 |

0.1 - 2.5 |

4 - 16 |

| 610 |

305 |

30 |

0.1 - 2.5 |

4 - 16 |

| 610 |

305 |

45 |

0.1 - 2.5 |

4 - 16 |

| 610 |

305 |

50 |

0.1 - 2.5 |

4 - 16 |

| 650 |

500 |

50 |

0.1 - 2.5 |

4 - 16 |

| 915 |

305 |

30 |

0.1 - 2.5 |

4 - 16 |

| 1200 |

305 |

30 |

0.1 - 2.5 |

4 - 16 |

| 1220 |

515 |

40 |

0.1 - 2.5 |

4 - 16 |

4. Feature Advantage

- High mechanical strength.

- High stiffness and load capacity than ordinary metal screen mesh.

- Corrosion, heat and weather resistance.

- Beautiful surface with different colors.

- Can sort both dry and wet materials.

- Lightweight and easy to install.

- Long life. The polyurethane surface supplies a extra wear resistant surface for the screen, so it can improve the service life of the screen.

- Little noise. Plastic structure can reduce the noise caused by the stones and screen mesh.

- No excessive comminution. Made from soft material, thus it will reduce or avoid the excessive comminution.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!